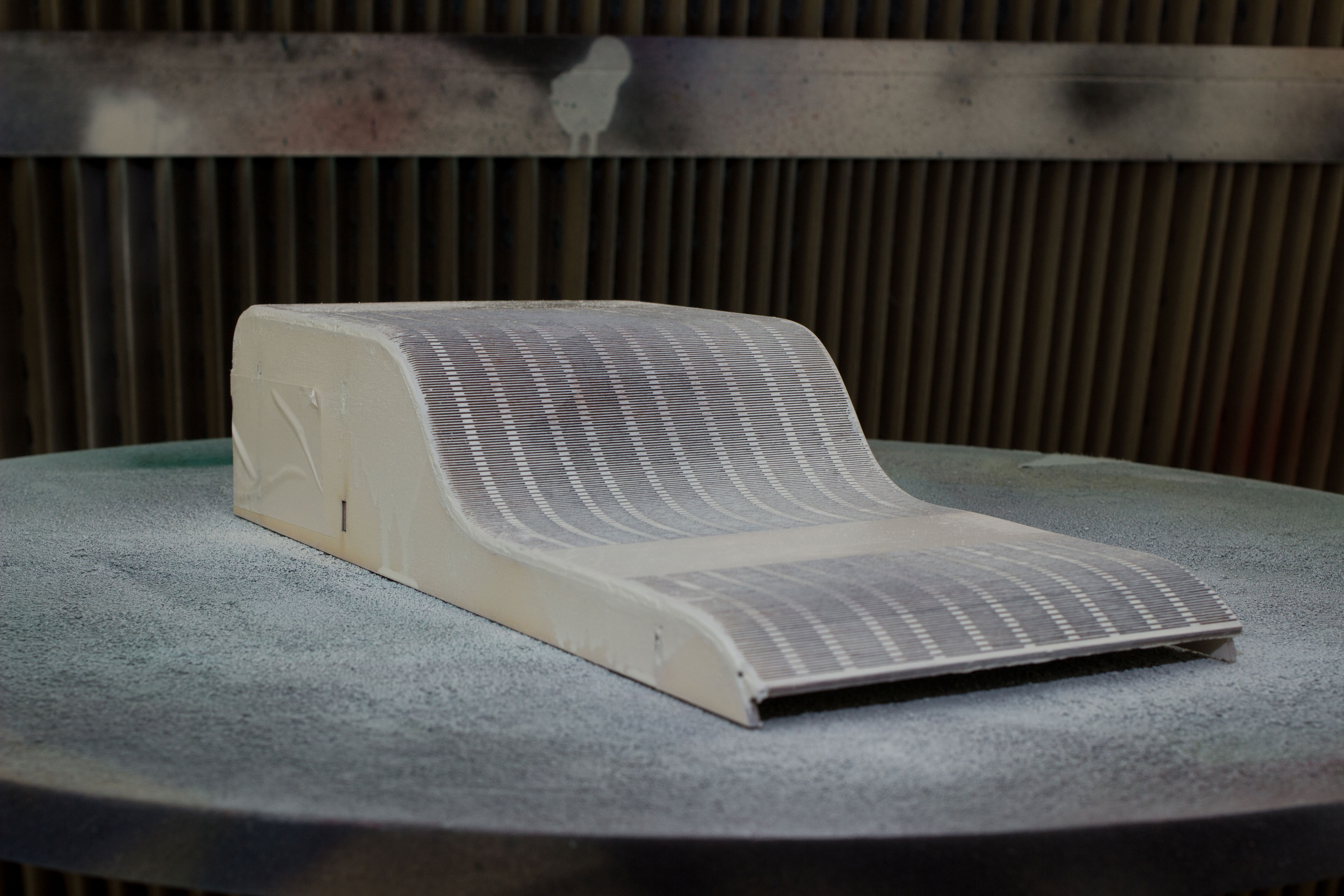

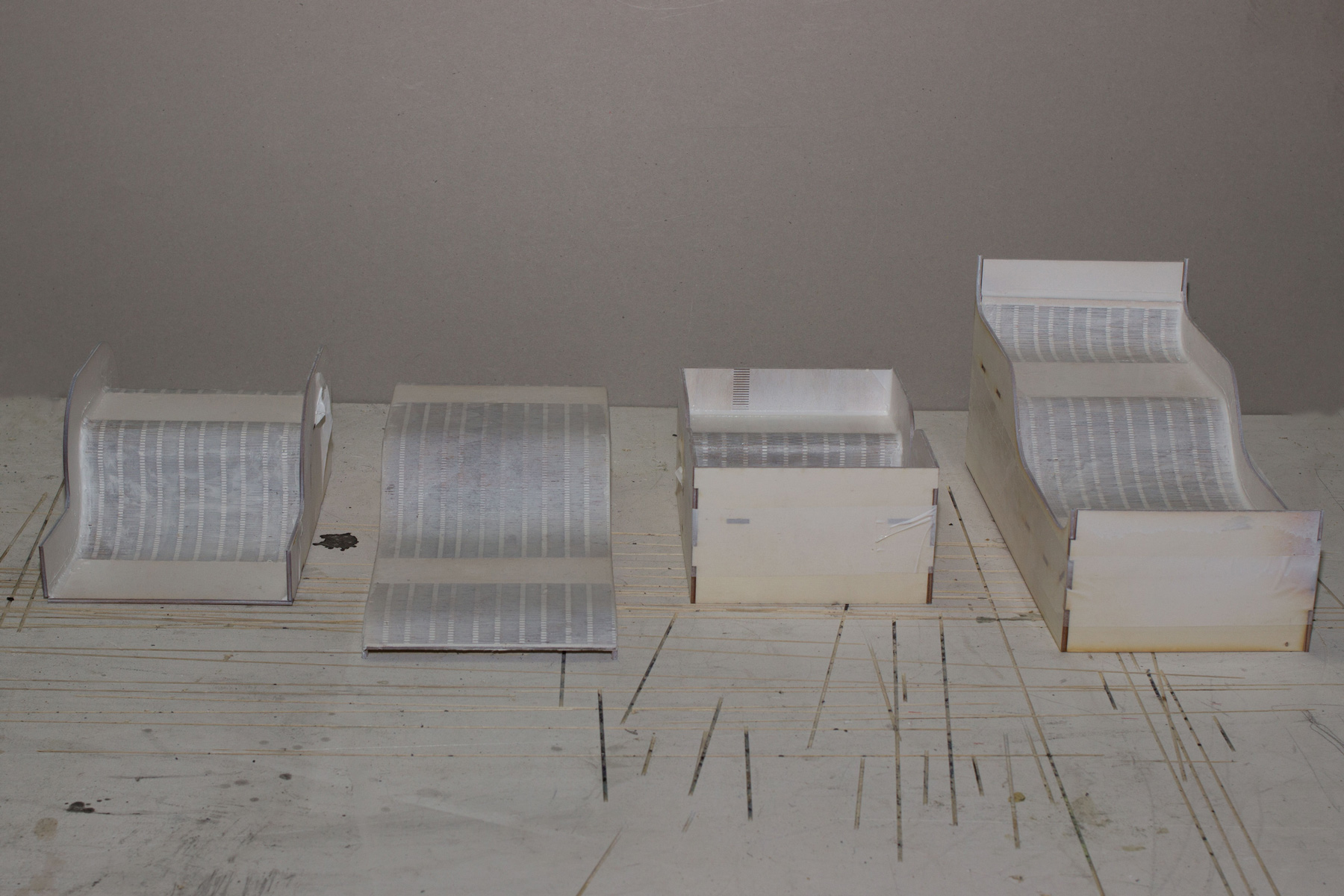

the molds

The three-dimensional mold models are broken down into their

two-dimensional components and laser cut into shape. To prevent

the mold and therefore the final object from having only right

angled corners, living hinges are used to create smoother round

curves giving the final shelf element a more organic feel. The remaining

corners and the living hinges are filled and rounded off

with silicon before the individual shelf elements can be molded.

Creating a modular system with elements variating in size, shape

and color allows the user to assemble a shelf fitting their needs.

Each element can be screwed directly into the wall making the

setup simple and allowing it to be changed easily along the way

by adding, removing or rearranging elements.